We have just bought a lovely new to us but actually very old house, I won't go into massive details other than it's 400+ years old, has solid brick walls, some secondary glazing and chews through gas.

Soon as we moved in it was clear the heating situation had not been designed by a heating engineer. Luckily there were two new ish greenstar i22 boilers connected to a low loss heater and then Y plan to the property.

The first thing I did was turn off one boiler, no way did the house have 50kw of heat loss. I then turned on boiler down from 70 to 60. Not knowing the heat loss of the house at the time it felt to riskly to turn it down to 40c with no control system or person on site.

I tried to find a heating system that could control both boilers and do weather compensation, the market is not full of these at all. There was a unit for £500 that could connect to both boilers to make them act as one, but then it still have the same issues of no weather compensation WC.

Running one boiler on the lowest power setting for 24 without cycling and mounting the internal and external data gave me a rough heat loss. Using this I could build my own software, more details below.

The Experiment

Does my weather compensation software beat out setting the boiler to 70 and leaving it to cycle?

The answer in my mind was obviously yes but after spending time and money buying hardware and coding software to control the boilers I wanted to know how much better.

The weather had predicted a week of near 0 for the next 3 days and nights and I knew it was the perfect time to run the system, heat loss at 0c outside and 15c inside gives an estimated usage of 240-260kWh of gas usage a day!

I ran the system in two modes, 1 mode using my weather compensation software. The other mode will be setting the boiler to 70c and letting the Nest thermostat keep the house at 15c. This is what the system was original profiled todo.

Controlled Variables

- The house is unoccupied.

- No electrics are on other than the boiler/pump

- No hot water demand

- The house was not entered during the experiment

- One boiler was disabled.

- The circulation pump was left at full speed throughout the tests.

- The house will be kept at 15c ±1c, the experiment will start at 15c ±1c.

The last point was key, the house has a-lot of thermal mass. Even though the heat loss is large with walls that are 20-40cm thick in places it takes a-lot of energy to get to a stable state.

Weather Compensation Controls

The system is actually pretty easy to understand, based on the heat loss of the house being a known value let's say for example 1kw per delta C. If it's 0 outside and you want to keep the house at 20c you would need the boiler to make 20kW of heating. Over a day that would be 20kW*24h = 480kWh. Knowing the power of the boiler let's say it's 30kW. You know you need the boiler to run at 66% power.

My system keeps an eye on the outside temp and the inside average temp across a large number of rooms. It works out what the base load of power would be. It also works out that any more gain is needed, So if the house is a few degrees under the required heating call it will boost the system. This is how I get it to be far more responsive.

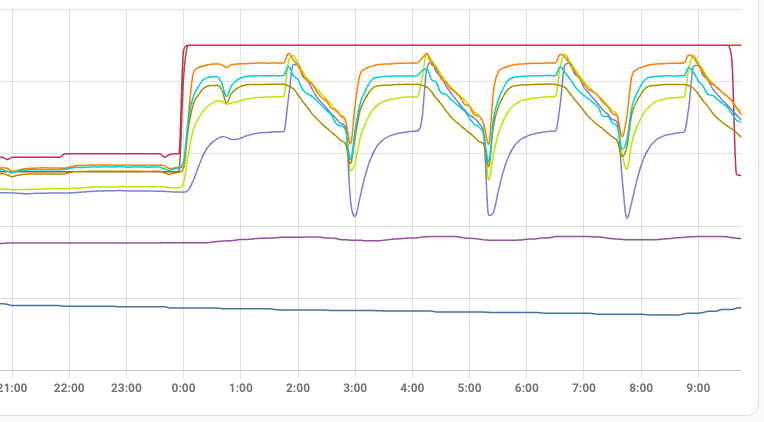

This can be seen in this diagram. The colder it is outside the hotter the boiler makes the water for the radiators.

Due to the demand being over the 30% min burning power my boiler can deliver the system should never cycle.

The old way

When we moved into the property the heating was set to 70c. That was it, the actual temperature of the house was controlled by the thermostat doing its on off cycle.

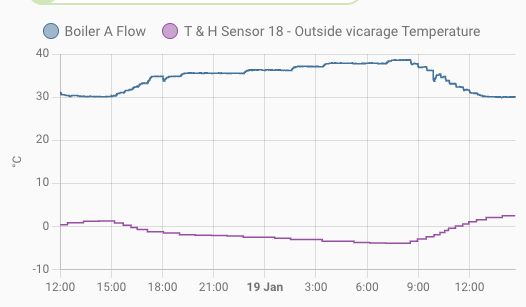

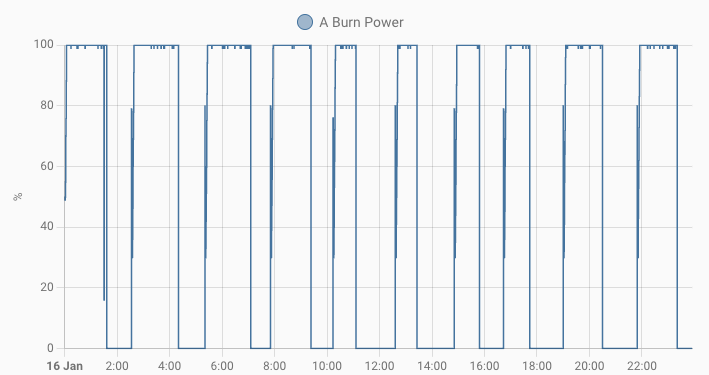

On the day of the 16th, you can see the boiler cycled 10 times. This is not actually that many times compared to most typical UK houses with oversized boilers and poor controls. The period and the time on can be seen to change during the day as the outside temperature changes. For example my old 2009 build house with a boiler than can only scale down to 10kw when the heat loss was nearer 3kw was cycling three times an hour.

The Final Results

The system ran the experiment for three days, two days using my control code and one day running at 70c.

| Gas Used (kWh) | Profile | Inside Avg C | Outside Avg c | Delta C | kWh per C | kW per C | Power Over Base | |

| 15th | 258.193 | WC | 15.44 | -0.54 | 15.98 | 16.16 | 0.67 | 0 |

| 16th | 319.704 | 70c | 15.91 | -0.13 | 16.04 | 19.93 | 0.83 | 18.94% |

| 17th | 251.007 | WC | 15.29 | -0.02 | 15.31 | 16.39 | 0.68 | -1.47% |

19% saving!! I didn't expect the system to be that much better at keeping the house warm. You can see the delta from the 15th and 16th was nearly the same.

Costs?

I am using Octopus Tracker pricing for gas, saving a good amount vs ofgems 7.42pence per kWh.

| Gas Used (kWh) | Price per kWH (£) | Price | |

| 15th | 258.193 | 0.0443 | £11.44 |

| 16th | 319.704 | 0.0425 | £13.59 |

| 17th | 251.007 | 0.0422 | £10.59 |

But why did it cost more to cycle?

Why did the boiler cost more to run on the 16th, why did it use more gas? That's all todo with how condensing boilers work. The lower the temperature of the return water to the boiler the more heat can be recovered from the flue gasses. This is the water vapour condensing back into water in the process releasing energy back into the water.

Contrary to common belief the less flue steam you can see the more efficient the boiler is burning. The vapour has condensed back into the water, releasing its energy into the return water. Next time you walk down the street look out for the steam, they are either having a shower or they have a badly tuned boiler.

If your boiler is not condensing you can scrap all of this writing, It won't make any difference go and get a new boiler or heat pump!

When the boiler was running at 100% it was not making as much use of these benefits.